Contact: Pierric JOSEPH

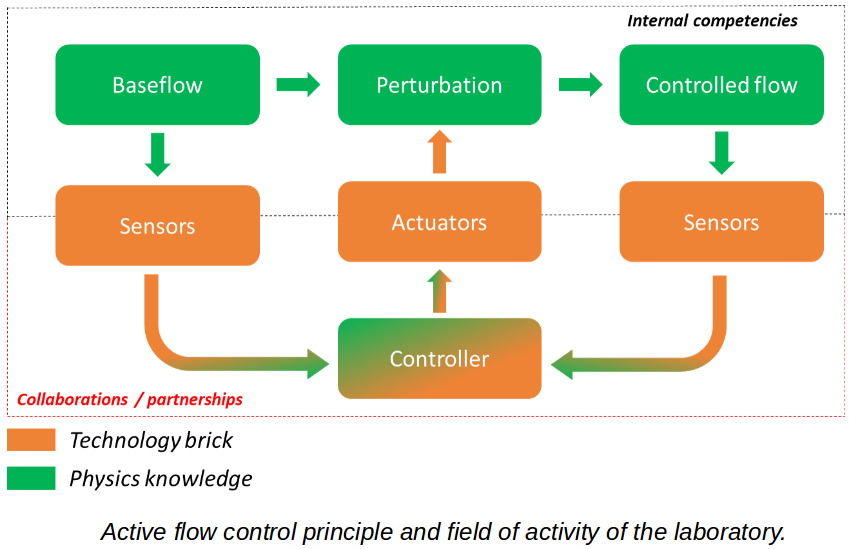

Research works described in this web page present LMFL’s activities carried out within the framework of the “Active Flow Control” transversal axis. This work deal with both academic test cases and others that are more industrial.

Active flow control is a highly transverse domain, located at the crossroad between various fields of science and engineering, with many technological aspects. This transverse research axis is then completely integrated in the main research axis of the laboratory and develops external collaborations and partnerships when needed.

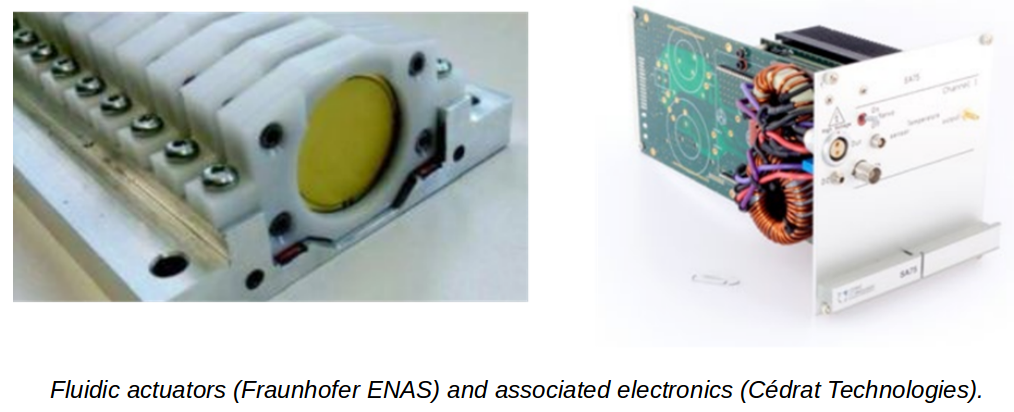

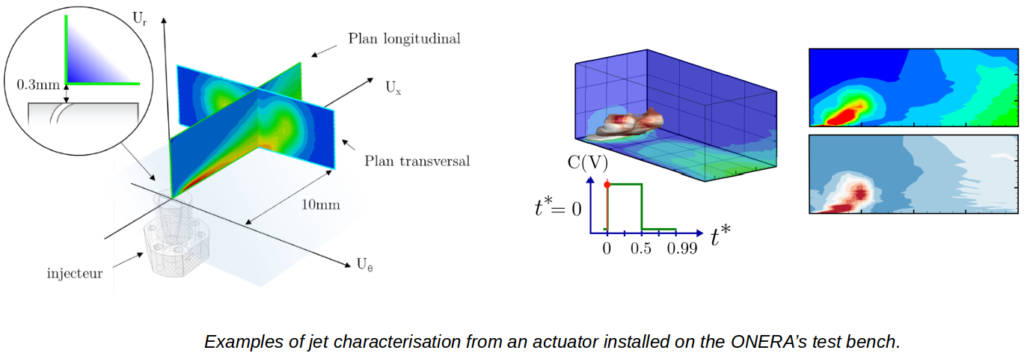

In an addition of an historical expertise in flow measurements, the laboratory has a strong competency in actuators characterisation, thanks to the scientific unit of ONERA Lille that runs a dedicated test bench.

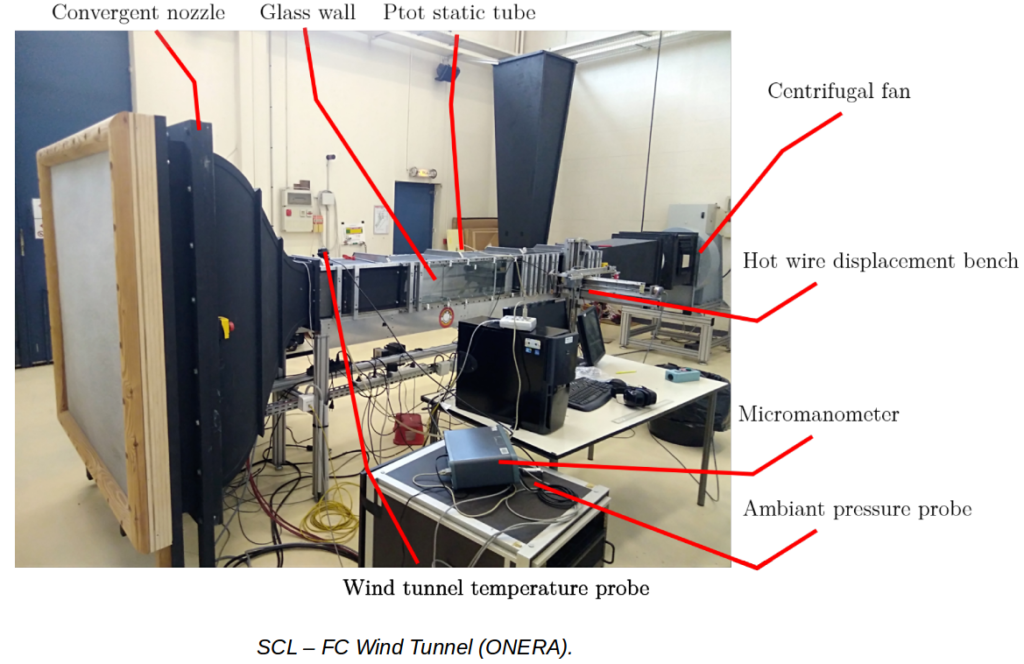

Measurements carried out on this test bench can be completed with additional tests carried out with a small size boundary layer wind tunnel (SCL – FC, 30 x 30 cm² test cross-section, VMAX = 40 m/s). It permits to perform calibration of the actuators with test conditions closer from the ones encountered on the applications. In addition, it allows the investigation in a more detailed manner of the physics existing between the injected perturbation and a turbulent boundary layer.

The laboratory also hosts some large size experimental facilities, like ONERA L1 and L2 wind tunnels and the large size boundary layer wind tunnel operated by Centrale Lille. All these installations are integrated into the CONTRAERO platform. These facilities allow to carry detailed analysis of external flows with active flow control, but also to study the mechanisms linked to turbulence and to the different length scales existing in the flow.

In addition, one of the specificities of the laboratory is its strong expertise in the application of active control to the internal flows of turbomachinery. In particular, the instabilities occurring in axial compressor, typical of aircraft engines, are studied with the CME2 axial compressor test rig operated at ENSAM Lille.

Some recent works and a strong dynamic inside the laboratory are also devoted to the development of the use of AI type algorithms (Neural Network) to reinforce the performance of control strategies.

List of recent and ongoing research projects in the laboratory

1. Regional funded projects CPER – FEDER: ELSAT2020 (2015-2021) and RITMEA (2021-2027)

LMFL is integrated into the regional initiative ELSAT2020 along with in its successor project RITMEA. These projects aim at addressing globally the problematic of the transportation. Expertise of the laboratory in fluid mechanics and aerodynamics, and in particular active flow control, is implemented within some sub – projects like CONTRATECH (reactive control of aerodynamic flows) and soon OCTAVE (Optimisation of aerodynamics and active control applied to vehicles).

This organisation allows close collaborations between regional laboratories and research centres working in transverse thematic like active flow control.

2. ANR NumERICCS (2015-2019)

NumERICCS project aims at coordinate efforts of several research groups (ENSAM Lille, Centrale Lille, UPMC, ONERA Lille and Safran Aircraft Engines). The goal of the project is to mitigate the destructive instabilities occurring in modern axial compressor at high pressure ratio using active flow control methods. It is a conjoint experimental and numeric study, with, as expected results, design, numerical simulations, and experimental validations of rotating stall control using pulsed jets located in front of the leading edge of the rotor blades.

3. CS ACONIT (2020-2023)

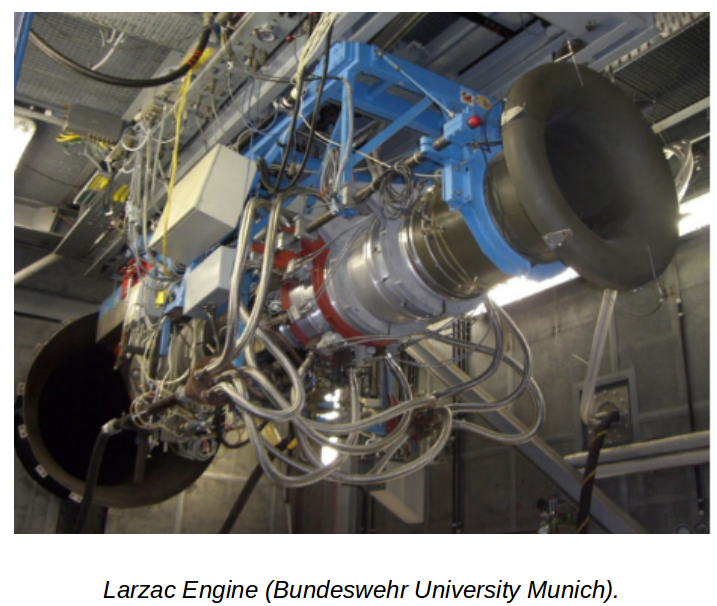

Sequel of the NumERICCS project, ACONIT is funded by European Union with the aim to increase the Technological Readiness Level (TRL) associated with flow control technology applied to aircraft engines, for the actuators in particular. A TRL 4 is planned, with a final demonstration on a real jet engine operated in controlled environment at the Bundeswehr University (Munich), relying on advanced actuators produced by the CEDRAT SMI from France.

4. INTACOO (2015-2020)

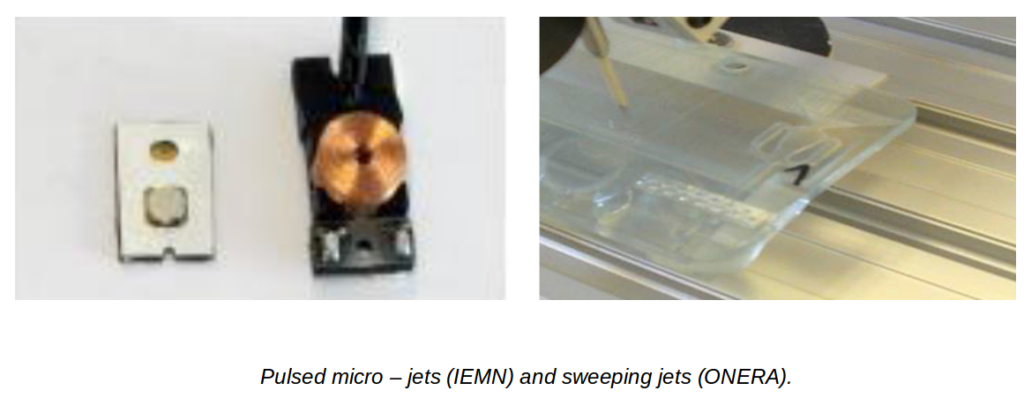

This project, funded by ONERA and associating IEMN, aims (for the laboratory perimeter) at testing various actuators technologies (pulsed and sweeping jets) on a separated flap configuration in the L1 wind tunnel, along with some pulsed micro – jets designed by IEMN for separation control on a cavity in collaboration with ONERA Meudon.

5. CAMELOTT (2014-2018) & CAMELOTT-MATVAL (2018-2022)

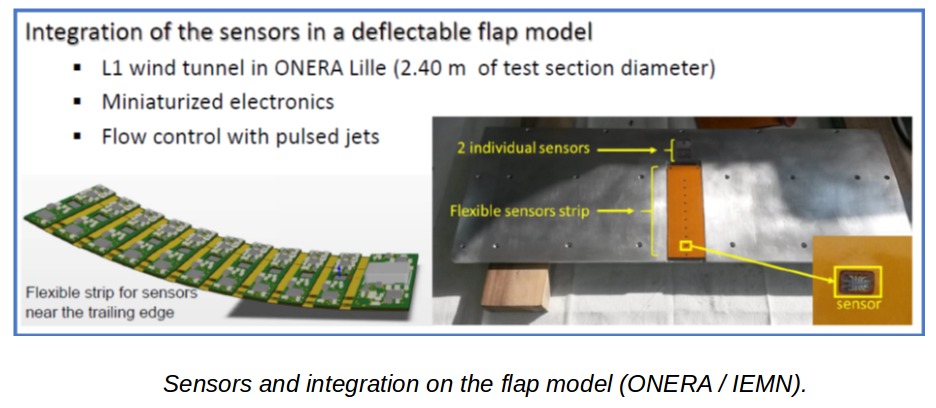

This IEMN coordinated project implies ONERA Lille and the SMI Thurmelec (ASTRID CAMELOTT) or the SMI SECAPEM (Maturation CAMELOTT – MATVAL). The goal of the project is to design and to test micro – sensors build with nanotechnology for measuring flow velocity and local friction coefficient. These micro – sensors are used in both laboratory experiments and flight tests. A dedicated experiment in the L1 wind tunnel aims at controlling the separation on a motorised flap using closed loop control.

6. ASPIC (2016-2019)

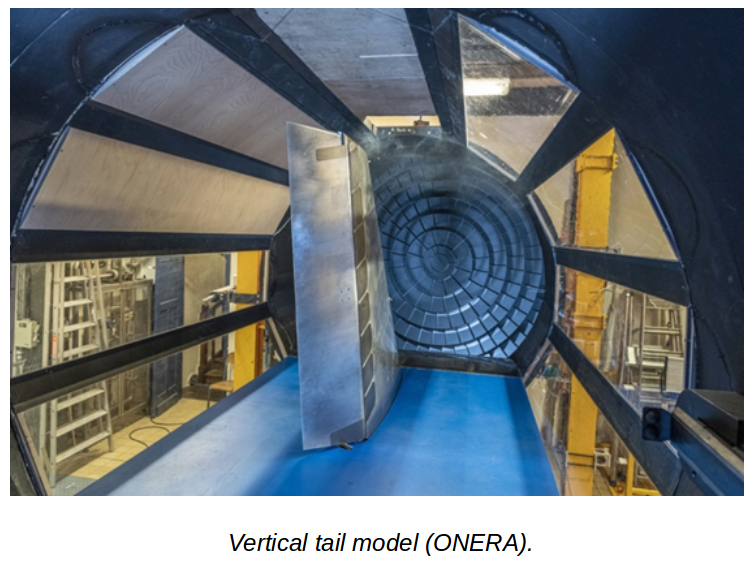

RAPID (DGA) funded project, associating ONERA and the SMI CTEC, it aims at testing in wind tunnel flow control solutions for mitigating separation on the vertical tail of a small size (business) jet with fluidic actuation. The goal of the control is to increase the side force generated by the tail by supressing the separation occurring on the control surfaces for high deflection angles. Two different types of actuators have been tested: synthetic jets (needing only an electric power supply) and sweeping jets requiring a pressurised air supply. It has been shown during test that control surfaces dimension could be reduced, leading to 3% drag reduction of the aircraft.

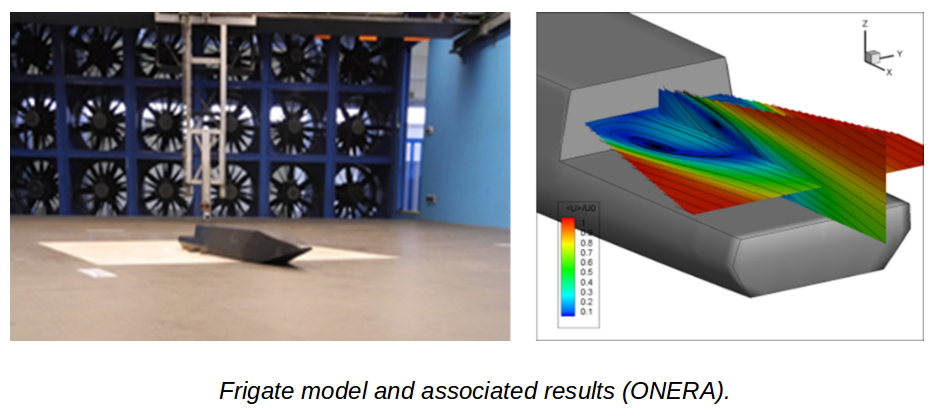

7. 7. Control of the flow on the rear deck of a frigate

ONERA has been working for a long time on naval aerology. After going deep into the complex physics associated with these particular flows (PhD thesis of B. Herry – 2010), ONERA is now interested in the landing process of helicopters in such situations (PhD thesis ONERA / Naval Group, 2020 – 2023). One of the investigated direction concerns the mitigation of the aerology constraint by using flow control on the rear deck of the ship. The L2 wind tunnel, with its large size, 6 meters, rotating ground, is an ideal tool in this purpose.

8. PRF FluiDyCon (2019-2022)

Fluid Dynamics Control: development of innovative approach for establishing command law for flow control. It is an internal ONERA project aiming at developing mathematical methods and numerical tools for controlling the dynamic of flow phenomena, in order to validate them numerically and experimentally.

9. CS2 SYNJET3C (2017-2021)

Numerical simulation and wind tunnel experiments of a synthetic jet actuator with and without crossflow.